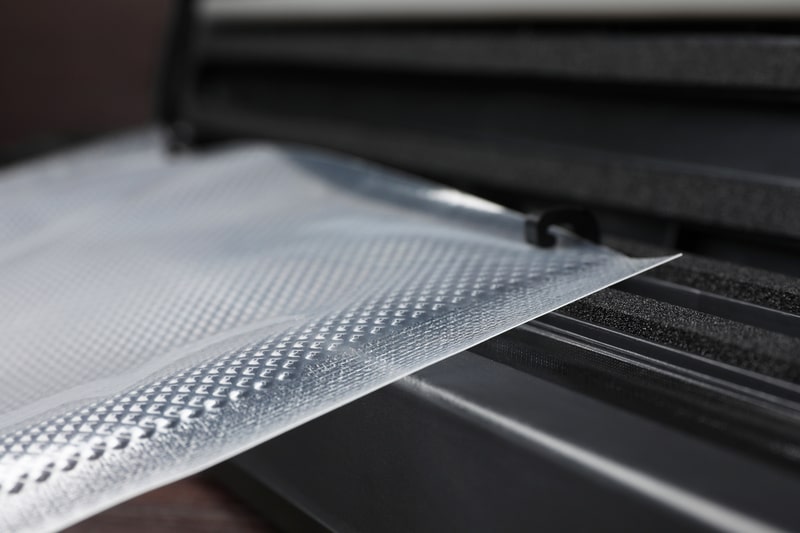

A vacuum sealer is an effective kitchen appliance that helps preserve meat, fruits, and vegetables. That’s because vacuum-sealing food items can extend the shelf life as it protects the food from freezer burns, dehydration, and bacterial growth.

Anova has designed a vacuum sealer with faster air extraction and a stronger seal. However, there are some problems associated with this vacuum sealer that you must know about.

Anova Vacuum Sealer Troubleshooting

- Not Vacuuming Properly

If the vacuum sealer is not vacuuming properly, it can negatively impact the preservation. There are various reasons behind vacuuming issues, such as using an incorrect bag, a damaged gasket, or a broken lid.

- Check The Bag

First of all, you should check the bag and make sure it is dry. Usually, people think that hot air coming from the vacuum sealer can dry the bag but it’s not the case and impacts the sealer’s ability to vacuum.

For this reason, you must dry the bag with the help of a disposable kitchen towel. Also, you must clean the ends properly and clear out the wrinkles. Secondly, you should check the bag for small tears. The vacuum sealer bags are not very fragile but they are still prone to damage.

So, inspect the bags and use duct tape to patch up the torn parts. However, if you have a new bag, it’s better to use it.

- Gasket

The vacuum sealer is designed with a gasket and it catches debris and dirt over time. The gasket is important for sealing the bags.

For this reason, you should open the vacuum sealer’s lid and locate the rubber seal (it’s the gasket) but make sure you unplug the sealer and let it cool down before you open the lid. If the gasket seems damaged or torn, you should replace it.

- Lid

The third solution is to check the lid. That’s because any structural damage to the vacuum sealer can lead to vacuuming issues.

For this reason, you must inspect the lid and make sure it’s tightly closing (it’s important for building the pressure). If the lid is damaged or loose, you should get it replaced.

- Drip Tray

If the drip tray is filled to its maximum capacity, it can also cause vacuuming issues. The drip tray is responsible for catching spilled food or liquid and needs to be regularly cleaned.

So, check the drip tray and clean it if it’s filled to maximum capacity. It will not only optimize the vacuuming functions but ensure hygienic preservation as well.

- Overheating

Last but not least, you must give your vacuum sealer a bit of rest. That’s because an overheated unit fails to perform and can lead to permanent damage to the internal components as well.

So, if the vacuum sealer is hot to touch, you have to turn it off for a few minutes, so it can cool down. The experts recommend turning off the vacuum sealer for twenty seconds after sealing one bag.

- Loud Noises

The vacuum sealer makes noise during vacuuming, but if the noise is too much, it’s likely that the exhaust filters are clogged. The exhaust filters are responsible for removing impurities from the air to ensure safe and hygienic sealing.

So, with time, the filters can get clogged with dirt and debris and start producing loud noises whenever the vacuum sealer is used. For this reason, we recommend that you check the exhaust filter and replace it if it’s clogged.

- No Heating

Anova vacuum sealer produces heat to make the bags are sealed properly. So, when there is no heating, you won’t be able to seal the bags. To fix the heating issue, you have to inspect the heating bar. It can be accessed by removing the top lid.

You have to use the multimeter to check the voltage continuity of the heating bar. The multimeter has to be connected with the heating bar and it will show the reading. If there is zero reading, the heating bar is burnt and should be replaced.

On the other hand, if the heating bar gives a reading but the vacuum sealer is not producing heat, you have to check the temperature band switch and relay.

For this purpose, we recommend that you hire an electrician as he can conduct live voltage checks on these points. If any of these components are damaged, you must get them replaced to optimize the heating process.

- Heating Doesn’t Stop

If you are done sealing the bags but the vacuum sealer is still producing heat, it’s likely because of the heating time relay. The heating time relay helps control heat flow in the machine.

So, if the relay is damaged or burnt, the heat flow won’t stop on time. The solution is to replace the damaged relay. In addition, make sure the socket contact is intact as well.

- Not Sealing Properly

The vacuum sealer seals the bags to make sure moisture or bacteria don’t contaminate the food items, resulting in longer shelf life.

However, if the vacuum sealer is not sealing properly, the air, moisture, and bacteria can get into the bag, which leads to food contamination. There are various reasons behind sealing issues, such as;

- Bag

First of all, you have to check the bag to ensure you haven’t overfilled the bag. You must consult the user manual and find out the maximum filling capacity of the sealing bags. So, if overfilling is the issue, just reduce the quantity of food in the bag and try sealing again.

Also, if you have to store more food, you should invest in bigger bags. In addition to this, always use dry bags and make sure there are no tears on the bag. Lastly, always clear the wrinkles from the bag.

- Heating Bar

Heating is important for sealing, and if the bar heating stops working, the vacuum sealer won’t be able to melt the sealing parts of the bag together. The heating bar in the vacuum sealer is responsible for converting electrical energy into usable heat.

So, when the heating bar stops working, it won’t convert the electrical energy into heat, hence the sealing issue. The only solution for a damaged heating bar is to replace it.

- Sealing Strip

The sealing strip is important to ensure tight and secure sealing. This means that a damaged sealing strip won’t be able to seal the bag’s ends together.

So, inspect the sealing strip, and if it seems damaged, make sure you get it replaced by a professional as it has to be properly installed to work properly.

- The Bag Melts

The bag melts when you use ordinary ones to preserve the food. This issue is not associated with the vacuum sealer, so just invest in original vacuum sealer rolls and bags.

- The Bag Starts Inflating After Sealing

If the bag starts inflating, you likely sealed fresh vegetables and fruits. That’s because fresh fruits and vegetables cannot be stored at room temperature once they have been vacuumed and sealed because they undergo the respiration process. So, always put the sealed bags in the freezer or refrigerator.

- Weak Suction

The suction feature of the vacuum sealer is responsible for sucking out the moisture and air packets to make sure the bags are properly sealed and food lasts a long time. However, weak suction can lead to bacterial growth and freezer-burned food.

The first solution is to check the lid and ensure that the latch is closed and no debris hinders the closure. Keep in mind that the latch should click when you close it. Secondly, you have to check the gasket and make sure it’s properly installed.

The gaskets must be installed in place and shouldn’t have any debris. If the gaskets seem dirty, clean them with soap and water solution. On the other hand, if the gasket is worn out, it should be replaced.