You can preserve a wide variety of veggies in the pantry by canning them, from green beans to carrots, corn to peppers. Even though NESCO has introduced pressure canners, the practice of canning has deep roots in history and can be done traditionally.

Issues with NESCO pressure canners can affect the preservation procedure and may potentially ruin the food. Let’s dive deeper into them! By writing this essay, we hope to shed light on widespread issues and offer practical advice for dealing with them.

NESCO Pressure Canner Problems

- Liquid Oozing Out

Without water, canning would be impossible; thus, it’s a problem when liquid leaks out of the pressure canner. Let’s take a look at some of the reasons for this problem.

- Pressure

When using a NESCO pressure canner, the pressure inside the canner can drop unexpectedly once the processing time has ended.

Furthermore, liquid leaking occurs when the pressure in the pressure canner continuously fluctuates throughout the process. This problem can be fixed by waiting at least 10 minutes after closing the lid for the pressure to decrease on its own.

- Air Bubbles

Liquid can leak from the jars if there are still air pockets. The pressure canner must be turned off. Then, remove the jar and use a plastic spatula to get rid of these air bubbles.

Combine the contents of the food container while eliminating any trapped air. After the air has been squeezed out, seal the jar, and it is good to go!

- Seal & Ring Band

While using a pressure canner, it is important to monitor the ring band and the seal. The liquid will leak if the ring bands are not placed correctly or the seal is inadequate.

Therefore, the pressure canner must be well sealed before use. In addition, the bands should be tightened regularly to keep water inside the rings, but never to the point of breaking.

- Temperature

Liquid escaping or oozing is an issue that arises when the pressure canner’s temperature isn’t controlled correctly or consistently. Therefore, keeping a steady temperature is essential for canning, so ensuring it’s adequately set is essential.

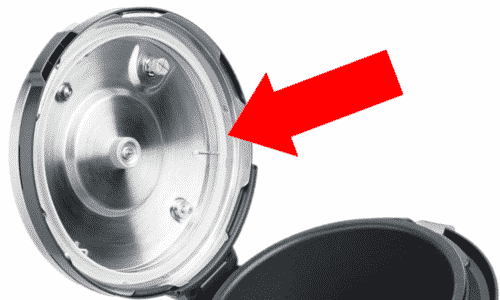

- Issues With The Lid

The lid must fit in for the NESCO pressure canner to function correctly and make your food perfect. However, if the lid doesn’t close properly, consider the following reasons and remedies;

- Locking Lugs Lining

Problems with the pressure canner’s lid’s location can occur if the locking lugs aren’t correctly aligned. When using a pressure canner, the lid must be placed on top of the canner, and the lid’s handles must be removed from the canner.

By sliding them into place, the locking lugs can be aligned and made to fit snugly against one another. Consequently, the top will slide in and rest against the lid. Additionally, you can make the gasket slide more easily by coating it with vegetable oil.

- The Lid Won’t Come Off

What’s Wrong: The lid of the pressure canner is tough to remove, even when the appliance has been switched off. It’s possible that if the pressure is removed too quickly, the resulting pressure won’t be enough to prevent the lid from jamming.

The machine may have reached an unsafe level of internal pressure. If there’s too much pressure, you can try pouring cold water over the lid. If that doesn’t work, try turning the pressure valve off. If this works, the pressure within should slowly dissipate, and the lid will become less tightly secured.

- Unable To Build Pressure

Some users have reported that the NESCO pressure canner doesn’t reach high pressures sometimes. If you find yourself in a similar situation, below are a few reasons and solutions.

- Gasket

Your pressure canner isn’t generating enough pressure, which is where the problem lies. A gasket is a component of pressure canners that is susceptible to damage caused by wear and tear over time. Because of this, your appliance won’t build sufficient pressure.

You should check your pressure canner’s gasket and pressure valves if you notice that it is taking too long to build the desired cooking pressure. Changing the gasket could fix the issue if it has been severely damaged.

It is possible that the gasket in the pressure canner is leaking, preventing the necessary buildup of pressure. Please take off the gasket and put it in a bowl of hot water for ten to twenty minutes; this will help it relax.

You should also apply vegetable oil to the gasket before reinstalling it. If the problem persists after the gasket has been repaired, it must be replaced.

- Temperature

The temperature may be too low in the pressure canner, preventing pressure from being built. If so, it would be best to raise the stove’s temperature.

- High-Pressure Valve Pops

High-pressure valve stem clogging is indicated by the NESCO pressure canner’s high-pressure valve popping up. However, it would be better if you wait until the pressure canner has cooled down before beginning troubleshooting.

It’s not enough to clean down the stem only; the lid needs to be cleaned as well. It’s also essential to wash the jars thoroughly before storing them under pressure.

If the steam is leaking, it can lead to problems with pressure. Even if your pressure canner eventually reaches the necessary pressure, it won’t stay at that pressure for long enough because of how long it takes to get to that point.

This is arguably the most common problem with household items. Usually, a filthy or broken gasket is to blame for this issue. Inspect the gasket for apparent signs of wear and tear. There shouldn’t be any cracks in the gasket or crumbs stuck to the edge.

The gasket should be removed, washed with cold water, and reinstalled if any food residue is found.

- Food Takes Too Long to Cook

There are several potential causes for this problem, including overfilling the pressure canner with food or water, adding frozen items, using a too thick liquid, etc. Ensure the pressure canner’s lid, handles, and food are in good working order and aren’t adding to the problem.

There’s no point in trying to get the pressure canner to work if you’re not going to be able to do so. It’s cool to wait until the pressure canner has cooled down before attempting any repairs for safety reasons.

- Gasket Doesn’t Seal

Initially, the issue with the gasket sealing persists even with the replacement gasket. In most cases, it happens due to incorrect size.

Therefore, it is important to employ the correct gasket in the pressure canner if the gasket fails to create a seal. You should consult the user manual and select the gasket that NESCO recommends.

The Bottom Line

The NESCO Pressure Canner has been widely regarded as the benchmark in the industry for many years. Even though it is held in such high regard by many people, it still has certain shortcomings.

There isn’t much complexity to these problems, and the solutions are laid forth in this article. The proper maintenance of your NESCO Pressure Canner will ensure that it continues to perform dependably for years to come.

Hello. And help please. I put 4 quart jars of ckn broth into the canner. Added the 8 cups of hot water. It came to E10 for barely a minute, then switched to the canning time. I put the airtight position on and it is venting for most of the time. Why?

I was wondering if there was a fix for my canner not even getting any power.. Used it a few days ago W/B canning and it shut off in the middle of time.. now wont turn on at all.. no power.. is there something i can check. maybe a safety feature i am not aware of.. thx

I was wondering if there was a fix for my canner not even getting any power.. Used it a few days ago canning and it shut off in the middle of time.. now wont turn on at all.. no power.. is there something i can check. maybe a safety feature i am not aware of.. thx